What is a Composite Column?

Composite columns are a mix of two conventional basic structures: auxiliary steel and basic cement. As composite columns were by and large created after steel sections and fortified solid segments, their plan approach could have been founded on either steel or solid structure strategies.

Composite columns are a combination of conventional structural paperwork: structural metal and structural concrete. As composite columns were normally advanced after metallic segments and fortified solid sections, their structure technique could have been founded absolutely on either steel or solid plan strategies. However, steel column layout methods have differed from concrete layout methods in some of the essential approaches. No matter this, either design technique may be used as the premise for developing a layout technique for composite columns.

Types of Composite columns

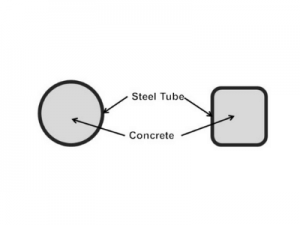

- CFST (Concrete Filled Steel Tube)

- CES (Concrete Encased Steel)

CFST (Concrete Filled Steel Tube)

Concrete Filled Steel Tube has been prominent for use as individual section components. The kept solid fill expands the hub load opposition however has little impact on the flexural obstruction. Consequently, it is improbable that these sections would be a decent decision for a minute opposing edge.

Filling the cylinder with solid will build a definitive quality of the part without a critical increment in expense. The fundamental impact of concrete is that it defers the nearby clasping of the cylinder divider and the solid itself, in the controlled state, can support higher anxieties and strains than when in the over the top state.

1. Flexural resistance of metallic is maximized using putting it at the perimeter of the go segment.

2. A metal tube prevents spalling and confines the concrete.

3. Concrete infill delays local buckling of the steel tube and offers compression electricity

4. Metallic tube replaces formwork and reinforcing steel.

Advantages of using CFST

- The use of concrete-filled tubular columns provides a great benefit saving by growing the region of the floor by way of a discount within the necessary cross-section dimension.

- This is very critical when constructing high-rise towers in cities where the appeal of letting areas is extremely high.

- Concrete, packed tubular columns in two orthogonal directions will offer excellent monotonic and seismic resistance.

- Uses with several bays of reinforced concrete-filled tubular column framing in each primary direction of a low-to medium-rise building provide structural stability when taking full advantage of concrete-filled tubular columns ‘ two-way framing abilities.

- Because of the composite nature, the benefits of the 2 compounds can be implemented as a standard composite structural product, and their negative aspects can be averted, thereby becoming a greater logical system.

- Due to the formwork for casting concrete and the shoring device in construction, the steel tubes can be used, which is why concrete-filled tubular column systems are much higher than concrete structures.

CES (Concrete Encased Steel)

They are generally used. The concrete encasement has frequently been taken into consideration as the simplest hearth and corrosion safety for the metal. However, in current years, lateral and now and again longitudinal reinforcement has been brought to the concrete encasement, and the consequent power of the steel and concrete interacting has been used for structural functions. A metallic form, encased in concrete, maybe thought of as reinforcement for the concrete.

A steel-solid composite segment is a pressure part, containing either a solid encased hot-moved steel area or a solid filled rounded segment of hot-moved steel and is commonly utilized as a heap bearing part in a composite surrounded structure.