Pre-stressed concrete is a type of concrete where the initial pressure is placed in the concrete before the external load is added in order to counteract the strain from external loads during the maintenance cycle in the desired way. High strength steel wire or alloys found in the concrete segment add this initial pressure.

The building process where cement is poured in a recycled mold and then cured in a controlled environment (prefabricated plant) is called prefabricated concrete. The cast structural component will then be shipped to the building site and installed. With precast concrete, architectural elements such as concrete frames, concrete walls, and concrete floors, etc. can be installed.

Why is Pre-stressed Concrete Required?

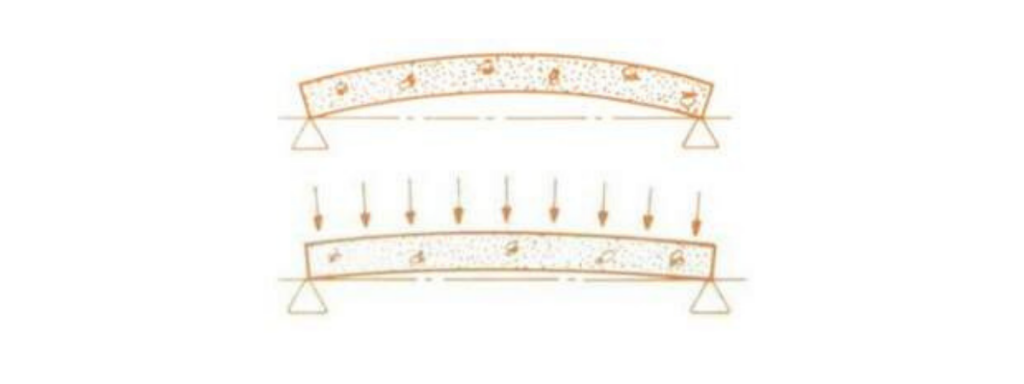

Sure, let’s go back to some fundamentals first before we get going. We realize that concrete is strong at pressure, but in stress, it is very soft. And so we see a stress area existed in the bottom of concrete during outward charging. Yeah, it’s trying to stretch, and guess what? It’s breaking. That’s why in the bottom section we install some steel bars so that it can withstand most of the stress and save cement from cracking. This is the conventional form of our RC. But what about some wider beam length mega-structures? Think of a flyover or popular Gateway Bridge in Australia, South Korea’s Incheon Bridge, or Sweden’s Ringhals nuclear reactor with very high external loads.

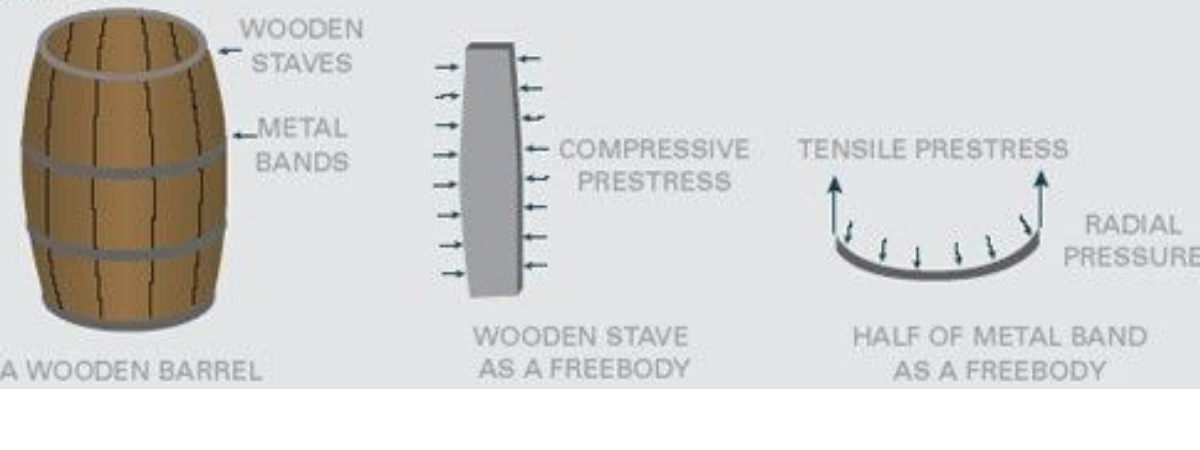

In the conventional RC design, we should provide greater depth for these wider beam lengths, which is often too much for boats to travel under the bridge for a bridge over a river. A new concept arrives here pre-stressed concrete. The definition of pre-stressed concrete is not that challenging. In reality, in our daily life, the tradition of prestressing stuff is much older. Imagine a barrel consisting of staves of wood and bands of iron. In the introductory chapter of his book “Construction of Prestressed Concrete Structures,” Tung-Yen Lin, a civil engineering professor at the University of California, clarified it.

The basic principle of prestressing was introduced to the building, possibly centuries ago, when the wooden staves were wrapped through ropes or metal bands to shape a barrel. They were under tensile prestress when the bands were tightened, which in effect caused compressive prestress between the staves and enabled them to withstand the tension of the hoops generated by internal fluid pressure. In other words, before being exposed to any operation loads, the bands and staves are prestressed.

Like this, the initial compression is provided in pre-stressed concrete to be offset by subsequent pressure loading.

How Pre-Stressed Concrete works?

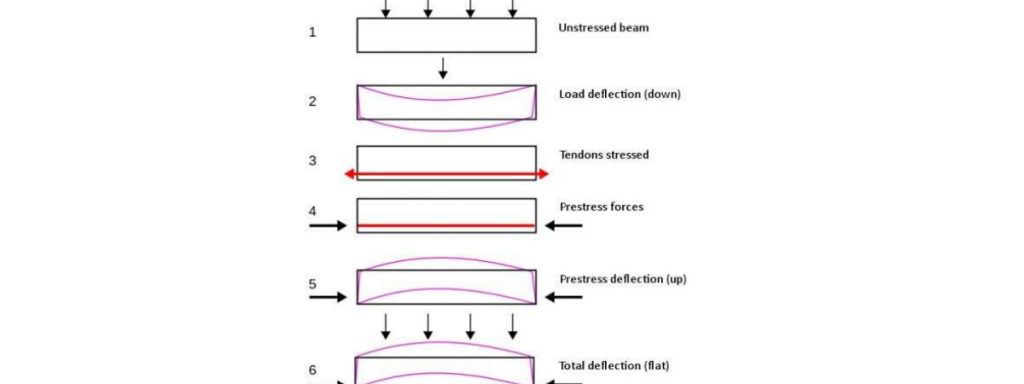

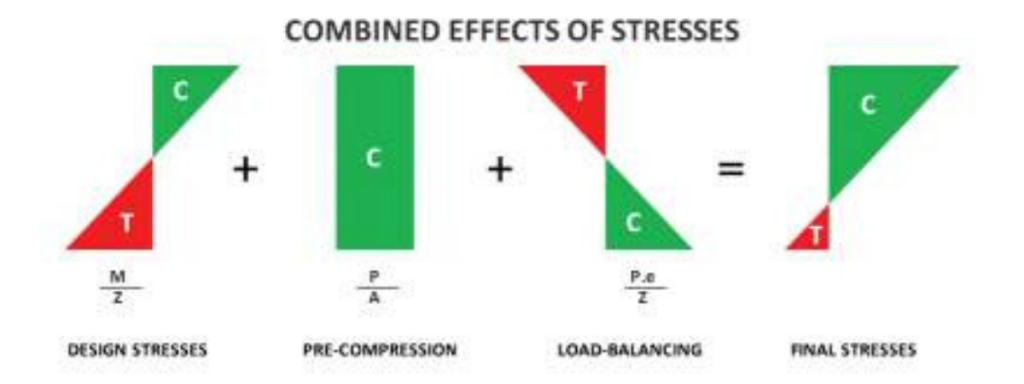

So I’ve got our idea right now. We’ve been studying why and when to use pre-stressed concrete. So how is it going to work? Throughout real life, metal wires of strong tensile strength are placed into the beam segment and are extended and secured and removed afterward. The steel tendon now wants to gain its initial duration and tensile stresses in the cement are converted into compressive stress. Now there are two forms of pressures on the beam after mounting,

- Internal prestressing force

- External forces (Dead load, Live load, etc.)

Which has to overcome one another. We’ll consider something like this when we glance at the moment diagram

Pre-Stressed Concrete Materials

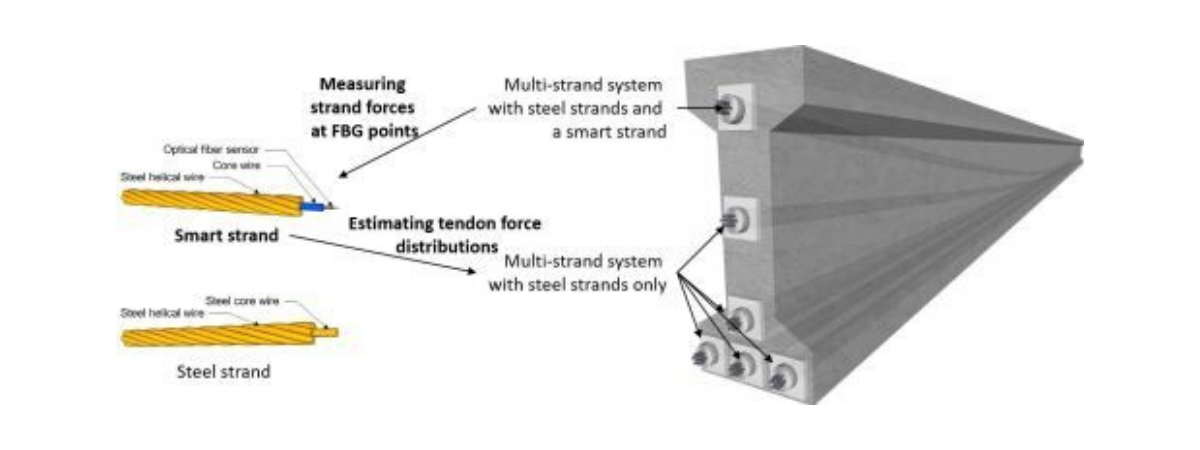

For pre-stressed concrete, high-strength seven-wire strings, high-strength steel wire or grade, and form alloys (as defined by the designer) should be used. For pre-stressed concrete, stronger concrete than standard RC is also needed. Generally speaking, a total of 5000 psi concrete cylinder capacity for 28 days must be used. Okay, why is this cement with high strength? Oh, if the cement is not solid enough when strained by tendons, it can be broken or collapsed. In addition to high compressive strength, it offers higher strain and shear resistance and is therefore suitable for pre-stressed concrete.

of contrast, the cement of high strength is less susceptible to shrinkage break. It has a greater elasticity component and lower stress for the crawl. As a result, there is a small loss of prestressing.

Prestressing eliminates a range of structural limitations of traditional concrete spaces on span and load, which enables the building of roofs, floors, bridges which walls with longer spans without support. It makes the design and construction of lighter and shallower concrete structures by architects and engineers without losing energy.