Ferrocement is a flexible type of reinforced concrete and has uniformly distributed wire meshes in the transverse section and cement mortar. This has special strength and serviceability qualities that are unmatched by other thin building materials.

Ferrocement was discovered by Joseph Louis in 1848 and is regarded as one of the first reinforced concrete applications. Due to obsolete manufacturing methods, the process had not been very widespread during the 19th century. Yet today, the right methods and techniques are being widely implemented with simple accessibility.

Methods for Construction of Ferrocement

The ferrocement manufacturing process depends on factors such as the design of ferrocement production, the availability of machinery for mixing, handling and positioning, expertise, and overall labor costs. It can be prepared with molds too. During ferrocement output, it should be ensured that there are high-level control requirements for achieving sufficient encapsulation with mortar or concrete matrix of several layers of the wire mesh reinforcement. The mortar will be compacted in such a way that air voids in the matrix are small. The methods for merriment construction are illustrated as follows.

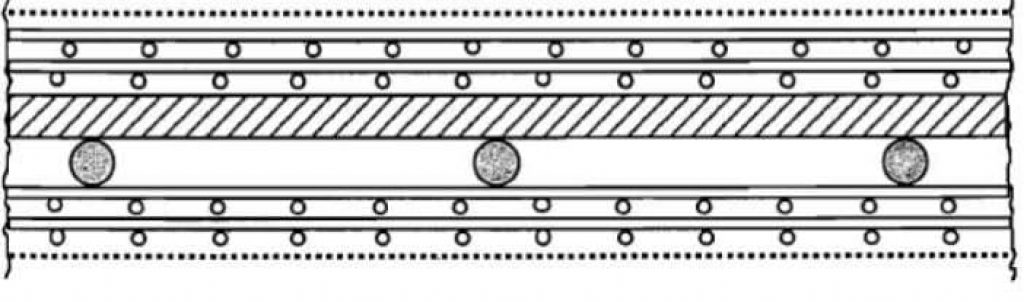

Skeletal armature method: Multiple layers of wire mesh are attached at either side of the reinforcement bars (skeleton steel) in the skeleton armature process. Instead, this whole structure is welded to achieve the desired form. The morter is then applied from one side allowing it to pass through the mesh layers until the excess mortar emerges on the other.

The skeletal steel is set in both directions at the center of the segment. It only serves as spacer rods and doesn’t contribute to the strength but contributes to the structure’s dead weight. The structural scale defines the diameter of the skeletal steel plates. It has to be cut to the length needed, bent according to the profile, and tied in a chain.

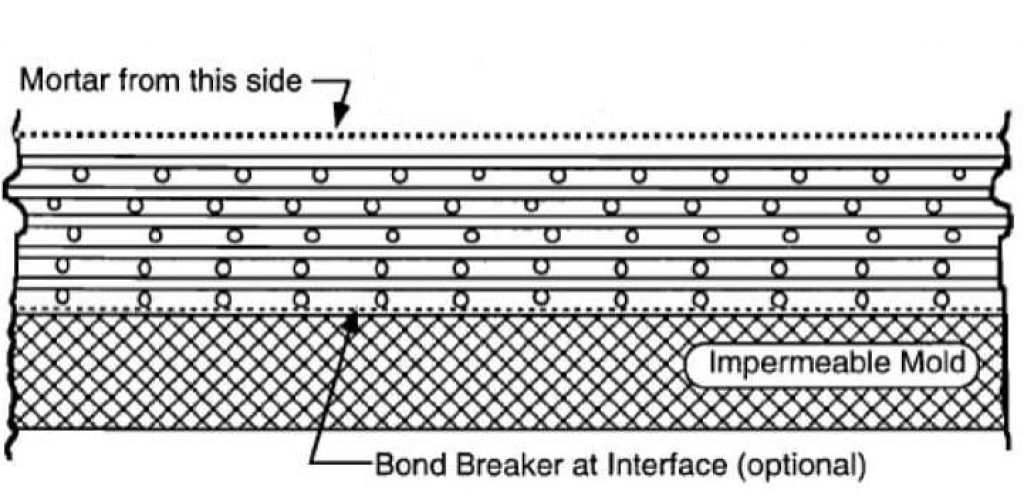

Closed mold method: The layers of wire mesh are either bound or stapled together in the closed mold process and placed against the surface of the closed mold, i.e., a female mold or a male mold. Before that, the mortar is applied from one side.

Although removing the mold from the ferrocement structure is not compulsory, it can be removed with release agents and other treatment agents, if necessary.

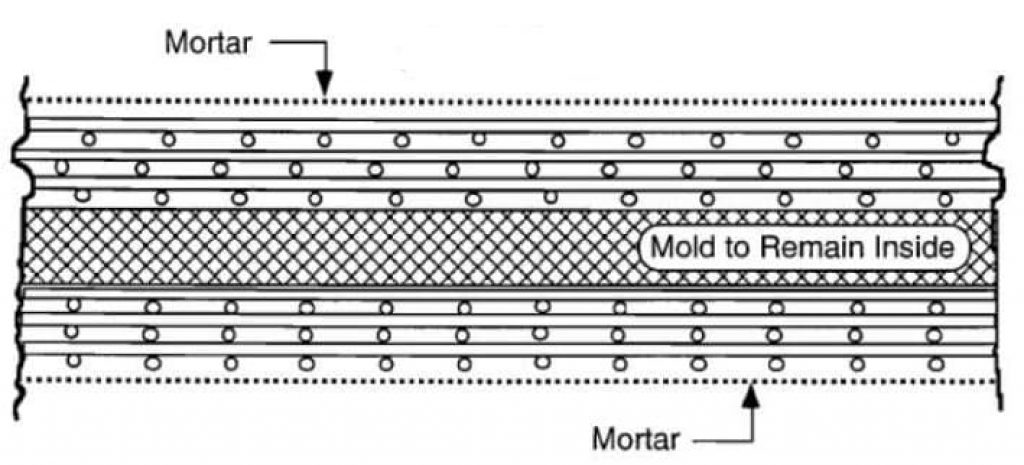

Integral Mold Method: As the name suggests, the mold serves as an integral part of the to be made structure. The integral mold, also known as the heart, is a semi-rigid frame with few mesh layers or a rigid foam with insulating materials like polyurethane or polystyrene.

Mortar may be mounted from one side or both. After it sets, by adding more layers of mesh with the application of mortar on both sides, the strength of the ferrocement can be improved. To order to produce an integrated structural structure, steps must be taken to create a solid bond between the mold and the layer applied later upon.

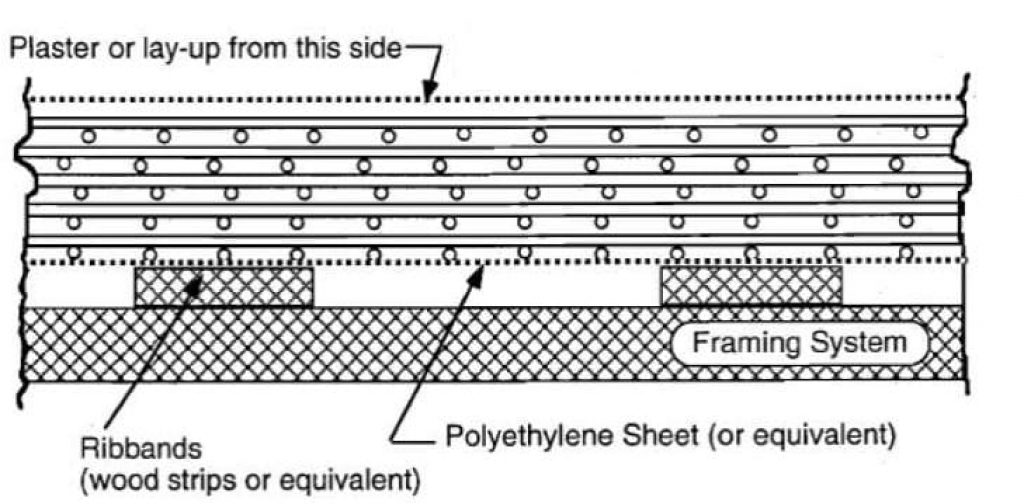

Open Mold Method: The process of open mold is somewhat identical to that of the closed mold. At first, the mortar is added to the open mold through one side of the mesh layers and rods. The mold is a wooden lined lattice. The type is either coated with a release agent or fully covered with sheeting of polyethylene.

A similar, but non-rigid and transparent mold will, therefore, be shaped. This allows the quick removal of the mold and enables any defects to be detected and corrected during the morter application process.

Read More:civilengineer-online.com

What is ferrocement?

Ferrocement is a flexible type of reinforced concrete and has uniformly distributed wire meshes in the transverse section and cement mortar.

What are the factors which affect ferrocement construction?

The factors influencing the ferrocement construction cycle are the complexity of ferrocement production, the availability of equipment for mixing, handling, and positioning, the expertise, and overall labor costs.