The following steps include the correct use of hydraulic concrete for maximum benefit:

Preparation

- The hydraulic concrete surface to be applied to cement should be clean. Dirt, dirt, grease, or loose fragments stop the concrete from adhering adequately to the floor.

- Hydraulic concrete is important that the temperature should be held between 45 °F (7°C) and 90 ° F (32°C) during initial recovery, as the concrete will not be frozen.

- Before adding concrete, the region should be saturated for 24 hours.

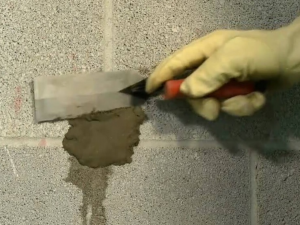

- Before the application of cement, small cracks and holes should be enlarged. It is necessary to avoid V-shaped wounds.

Mixing Cement

- Hydraulic concrete is recommended to mix the cement with a mechanical mixer with rotating blades to obtain a uniform mix.

- Before combining, the mixer should be filled with excess water and cleaned.

- The hydraulic concrete necessary amount of water is to be applied to the proper amount of dry hydraulic cement according to the orders of the supplier. Once it begins to set, though, the liquid should no longer be included.

- Small volumes of concrete should be combined at the same moment as it hardens very easily and must be put within 10-15 minutes.

- The Hydraulic concrete solution of concrete should be blended at a relatively low speed.

Applying Hydraulic Cement

- Hydraulic concrete is important to apply the hydraulic cement mix as quickly as possible.

- Bleeding or separation can result in unnecessary mixing.

- Any additional additives or admixtures should not be added unless stated in the instructions of the manufacturer.