Precast construction is one in which the concrete element is produced for assembly in a location separate from the building location. The individual components are manufactured by industrial procedure based on mass production, such that it is possible to construct a building in large number during a short period of time and even at low cost, making the system affordable. Some of the precast elements are shown in Figure.

Precast construction help to maintain high-quality control since the concrete quality can strictly adhere and the elements are produced at one place under supervision. It also gives reliable results in terms of final finishes. Since thin components are used there is a possibility in material saving. Moulds are repetitively used thereby decreases the cost of mould per unit. Precast construction does not affect due to different weather conditions. The waste generated during construction is also less compared to in-situ construction. Precast construction has many advantages such as weatherproof, acoustically versatile, thermally efficient, fireproof, lower refurbishment costs after a fire, inedible to termites and rodents, durable, structurally sufficient, dampness vibration, higher strength corrosion-resistant, resistant to chemical attack, resist against blasts, can be manufactured in many shapes and can be customized.

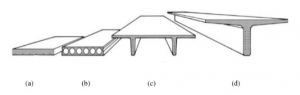

Precast= (a) Solid flat slab (b) Hollow core slab (c) Double tee (d) Single

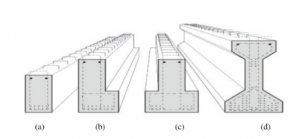

Precast= (a) Rectangular beam (b) L-shaped beam (c) Inverted T beam (d) I-Section

Types of Precast Construction:

Precast systems are mainly classified into four categories based on their load-bearing form. They are listed below:

1.Large-panel systems

2.Frame systems

3.Slab-column systems with walls

4.Mixed systems

Large panel systems:

In case of large panel systems, the horizontal and vertical panels are designed to resist gravity load. Usually, the wall panels are manufactured to a height of one storey. The floor panels i.e. horizontal panel when joined properly with vertical panels acts as a diaphragm which helps in transferring lateral loads to the wall.

A large – panel concrete building under construction

Frame Systems:

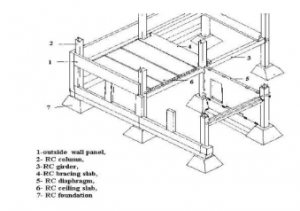

Large panel system construction

This type of construction as shown in fig 1.4 consist of linear elements i.e. beams and columns which are connected together to make a frame system. It is easier to connect linear elements when compared to spatial elements.

Slab column system with a shear wall:

In this type of precast system, the slab column system helps in resisting gravity loads whereas the shear wall helps to resist the lateral load. Fig 1.1 (e) depicts a slab column system. There are two types of systems under this category:

- Lift slab system with wall

- Pre-stressed slab column system

A lift-slab building

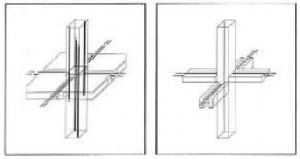

Post-tensioned slab-column connection

Mixed system:

It may consist of a combination of two or more systems as explained in previous subsections.