The specific gravity is usually defined as the ratio between the weight of a given material volume and the weight of an equivalent water volume. The cement portland has a common quality gravity of about 3.15. The price would come close to 2.90 As per the Portland Cement Association (PCA) when it comes to portland pozzolan cement and Portland blast-furnace cement. Kerosene is used to determine the specific gravity of cement, which is not recent for concrete.

Significance of Specific Gravity of Cement

The specific gravity can either increase or decrease based on the moisture content present in the cement. The particles of cement have pores or particles that may contain water in them. A marginal mix with a specific gravity cement 3.15 is prepared. Any adjustment in this particular gravity quality would influence the layout of the mix. Therefore, the basic gravity of the cement procured must be checked before mixing.

This is the main reason we neglect the use of old cement stock. External moisture content may affect old stock cement.

The basic gravity quality of cement is greater than 3.19 means that the cement was not properly minced into fine powder during its manufacture or that the cement has a lower moisture content. By the presence of chunks in concrete, the presence of moisture content in cement is easily identified.

Specific Gravity Test on Cement

Equipment and Apparatus

- Le Chaterlier”s flask.

- Weighing balance.

- Kerosene (free from water).

- Weighing Balance.

Specific Gravity of Cement Test Apparatus

The flask of Le Chaterlier is made of thin glass with a bulb in the middle. The bulb’s strength is almost 250 ml. The diameter of the bulb is 7.8 cm. The stem is in millimeters for graduation. Read More

The null graduation is from the top of the bulb at a distance of 8.8 cm. Another bulb has a length of 3.5 cm and a capacity of 17 ml at 2 cm from the zero. The stem is labeled with 18 ml at 1 cm from the bulb and grated up to 24 ml. The part above the 24ml mark is a 5 cm diameter funnel.

Procedure for Specific Gravity Test on Cement

- The flask can be fully dried and free of water and moisture. The spent flask’s weight is taken as W1.

- The container is filled up to half with cement (about 50gm of cement) and sealed with a stopper. The system is weighed and taken as W2 with the stopper.

- The top of the bottle is attached to this kerosene. The solution is thoroughly mixed, eliminating air bubbles.

- Weighing and taking the flask with kerosene, cement with the stopper as W3.

- The flask is then drained and filled to the brim with kerosene. This weights and takes the structure as W4.

Observations and Calculations

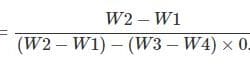

Specific Gravity of Cement Sg is given by the formula,

Here, the specific gravity of kerosene is 0.79g/cc

- Duplicate determination of specific gravity should agree within 0.01.

- To get an accurate result, the flask should be held at a constant temperature before each reading is taken.